SPACE FRAMES:

Technical Foundations

Description

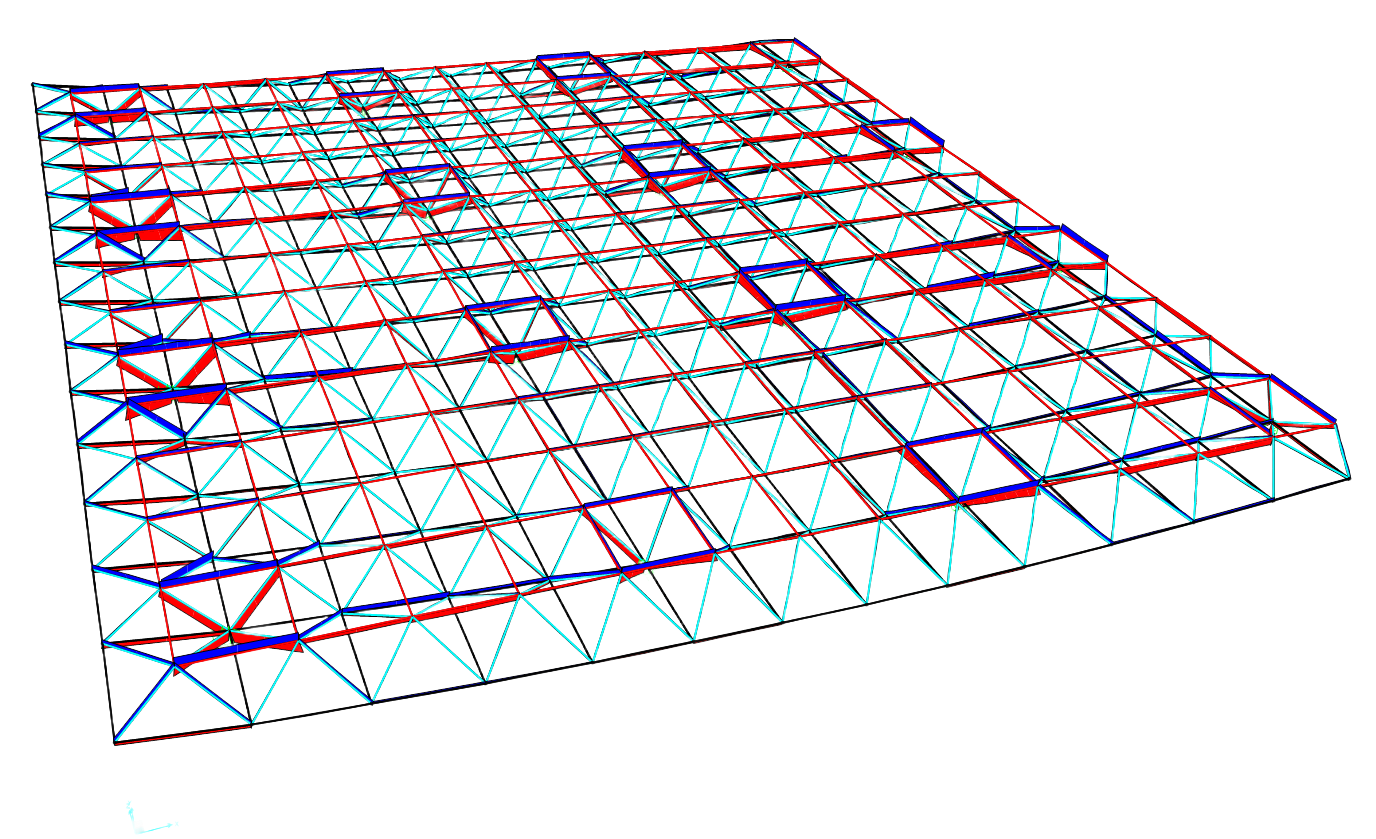

Space frame structures are three-dimensional structural systems made up of bars and nodes that work together. Their structural behavior is based on the spatial distribution of stresses, allowing them to span large distances with high stiffness and low self-weight.

They are used when structural efficiency, modular repeatability, and geometric freedom are relevant constraints of the project.

They allow for high-quality finishes because they are prefabricated and safe work in the field, as they are usually bolted structures that are sent to the construction site fully finished, being assembled like a large Meccano set, without welding.

Structural principle

A spatial structure functions as a three-dimensional network of bars under axial loads. They work only under tension/compression. Spatial triangulation provides:

- High overall stiffness

- Good distribution of effort

- Structural redundancy

- Stable behavior under variable loads (especially earthquakes).

Unlike two-dimensional systems (trusses or frames), stiffness is achieved through three-dimensional geometry. This makes the overall behavior of the structure resemble that of a slab (very rigid in two directions), allowing for different support arrangements.

Common applications

- Large span roofs

- Transport stations

- Sports halls

- Airports

- Architectural atriums

- Buildings with unique geometries or special conditions.

structural advantages

- High stiffness-to-weight ratio

- Modularity and prefabrication

- Good performance under dynamic conditions (especially seismic)

- Possibility of complex geometries without significant cost increases

- Material optimization compared to traditional solutions. Lightweight

technical limitations

- A large number of joints. Many simple elements to form the structure.

- Sensitivity to manufacturing tolerances. The joints between elements must be well-defined and executed, or internal stresses that are difficult to control will be created.

- Need for geometric control during assembly. The large number of components requires rigorous assembly control.

- Engineering and detailing costs are higher than those of conventional systems

Frequently Asked Questions (FAQ)

What spans can a space frame structure reach? Typically between 30 and 100 meters without intermediate supports. In exceptional cases, it can far exceed these figures.

What is the difference between a space frame and a traditional truss? A space frame operates in three dimensions, while a truss is essentially a planar system. This provides greater overall rigidity with smaller structural dimensions (less weight).

What regulations apply to the calculation of spatial structures? Structural Eurocodes (EN 1990–1993), the Spanish Building Code (CTE), and specific regulations depending on the type and country. The same as for other steel structures.

Do they require nonlinear analysis? In demanding projects, yes: especially for stability control, geometric imperfections and stress redistribution, as well as for seismic or dynamic load calculations if required.

urban engineering

Specialized in the analysis and optimization of spatial and single-layer structures